In a previous article, we explored why, ideally, a pump should not endure dry running. Let’s now examine if a pump CAN survive dry running under system upset conditions.

SiC bearing material does not tolerate mechanical shock, which is what occurs when there is insufficient lubricating liquid between the bearing component surfaces, leading to contact between the components. There are several situations during system operation that can produce such conditions.

What are Some Common Upset Conditions?

The following are considered system upset conditions, during which the bearing lubricating film barrier is compromised:

• operation of the pump with valves closed

• insufficient pressure at the pump suction (inadequate net positive suction head available [NPSHa]) causing cavitation

• extended periods of operation at extremely low flow conditions

• extended periods of operation at high flow conditions with low pressure resistance at discharge—operation “off the curve” or beyond the maximum flow range

• excessive cycling of system flow from one flow rate to another

• excessive temperature that causes pumped liquid (lubricating flow) to vaporize at the bearing component surfaces—or not enough internal system pressure to keep the pumped fluid in liquid state as it passes through the pump

• energizing motor without liquid in the pump, including briefly to check rotation

• plugged impeller vane inlet at suction eye

Enhancing SiC Bearings

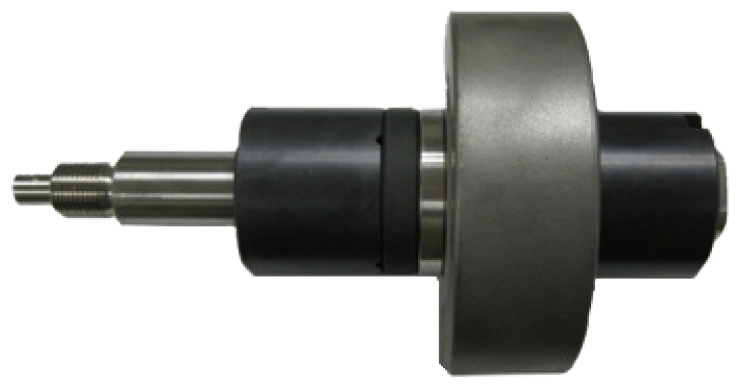

Specially treated sintered SiC-X bearings are available from Magnatex to provide enhanced dry-running capabilities in the case of a system upset condition. All of these are called diamondlike coatings (DLC). Some manufacturers use coatings that adhere to the substrate SiC, while Magnatex uses infusion methods that mechanically integrate the coating into the base material. Integrating the diamond-like substance into the bearing ensure that the bearing will last longer verses those that simply coat the bearings’ surface. These treatments substantially reduce the surface coefficient of friction compared to that of standard sintered SiC. Less friction during system upset and other dry run conditions generate less heat, reducing the potential for bearing component breakage from mechanical contact or thermal shock.

Specially treated sintered SiC-X bearings are available from Magnatex to provide enhanced dry-running capabilities in the case of a system upset condition. All of these are called diamondlike coatings (DLC). Some manufacturers use coatings that adhere to the substrate SiC, while Magnatex uses infusion methods that mechanically integrate the coating into the base material. Integrating the diamond-like substance into the bearing ensure that the bearing will last longer verses those that simply coat the bearings’ surface. These treatments substantially reduce the surface coefficient of friction compared to that of standard sintered SiC. Less friction during system upset and other dry run conditions generate less heat, reducing the potential for bearing component breakage from mechanical contact or thermal shock.

In reference to pumping equipment and product lubricated bearings, no one recommends that the pump be operated without liquid passing through it. There is some residual liquid that remains when the unit loses suction but that will quickly be pressed out of the sides of the bearing components with continued operation. Vaporization of the liquid can occur quickly depending on the size of the pump.

How Long Can Enhanced SiC Bearings Last?

Definitive dry run times would require specific testing of the pump size and conditions of service in question. For small pumps under 2 horsepower (hp), testing has shown that the dry run time is minutes and can be stretched to more than an hour for the smallest pumps with the DLC coated bearings. The greater the power input to the pump, the shorter the time period before damage occurs in the bearing system. For larger pumps in the 50-plus-hp range, while DLC coatings will still help, the time before damage occurs remains quite short. Energizing the motor to check rotation of a pump without DLC coated bearings or liquid in the unit will likely result in some bearing damage. Damage from dry running will initially appear as cracked or chipped SiC components. As the liquid vanishes and the rotating ceramic components come in contact with stationary components, the SiC can shatter, breaking into small pieces. Continued operation damages more pump components such as the shaft, rear casing, casing cover and impeller—all of which are costly parts. This type of damage to the pump is preventable.

What About Other Bearing Types and Seals?

Lined, mag drive pumps use either SiC or nonmetallic bearing materials. Some of the latter may have enhanced lubricity but are still subject to the same axioms of running with compromised lubrication.

Canned motor pumps, the other sealless centrifugal type, typically use softer bearing materials including carbon that are more lubricious, but susceptible to wear. These require a bearing monitor system to avoid component damage.

With mechanically sealed pumps, seal faces operate on a similar hydrodynamic film and require the same type of lubrication. They will not run dry long without damage either.

How to Prevent Dry Running

Again, it is recommended that the pump be protected by a power monitor and that the low power trip point be set at a level representing the first indication that suction has been lost. Setting the low trip point time delay at less than 2 to 3 seconds can prevent tripping of the pump when a large bubble of vapor/air vents through the pump without losing suction. Trying to run longer to empty the suction line of product will result in damage to the pump that is more costly than the small amount of product that may remain in the suction line. A properly set power monitor will save money for the pump owner in several enterprise accounts.

Conclusion

Most damage to mag drive pumps can be avoided. So in revisiting our original title question, “How long can I run my pump dry?” we should instead ask, “Can I or Should I run my pump dry?” Our qualified, “yes,” means that while you CAN run your pump dry, it should be avoided.