- Home

- /

- Ancillary Products

- /

- PA/PB Assemblies

For Quality Management System:

(Applicable for IAS Accredited Certification)

ISO 9001: Registered

PA/PB Assemblies cost a fraction of the sum of their component parts, so that they are the most cost effective way to spare your critical Magnatex pump(s).

Fig. 1 Wet End Assembly (PB)

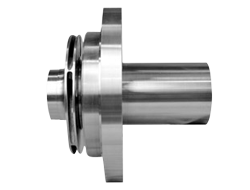

Fig. 2 Outer Magnet Assembly

A PB Assembly is a completely assembled wet end rotating element (Fig. 1) consisting of the rear casting, inner magnet, Sic(X) bearing system, casing cover and impeller. A PA Assembly consists of the PB Assembly PLUS the outer magnet assembly (Fig. 2).

PA/PB assemblies are the quickest and easiest way to get your process back up and running with minimal downtime and lost production. As an added benefit, once the old assembly has been removed from the pump you can purchase whatever spare components you need to repair it and put it back into your spares inventory for future use.

The Magnatex Slip-Fit Construction allows easy maintenance of the Mag-Drive pump. There are no special tools required for disassembly, or fragile tolerance rings for assembly. For safety, there is no need to heat bearing cartridges to very high temperatures to remove or install process bearings, as in some competitive designs.