- Home

- /

- Pumps

- /

- Mag Drive Centrifugal Pumps

- /

- MAXP

For Quality Management System:

(Applicable for IAS Accredited Certification)

ISO 9001: Registered

MAXP Series Pumps

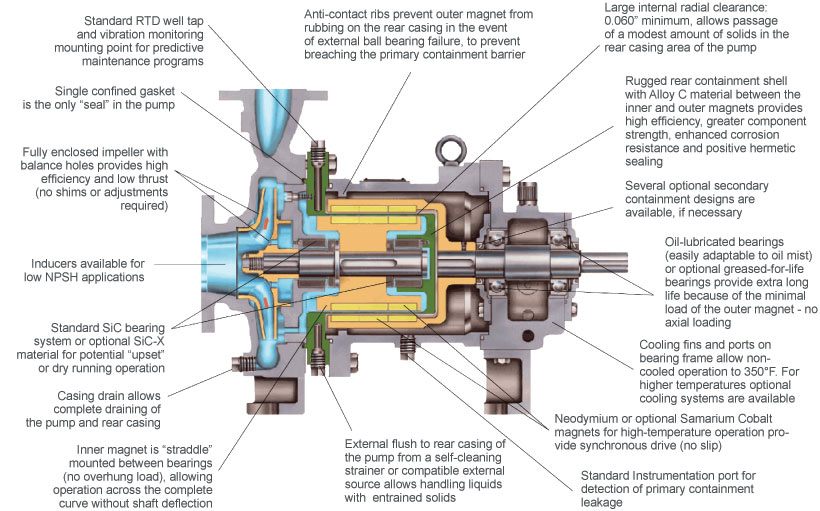

Magnatex MAXP pumps have the following design features:

Materials of Construction

Connect with a Magnatex representative to learn more about our products or to request a quote.

Contact Us

MAGNATEX® MAXP Series Specifications

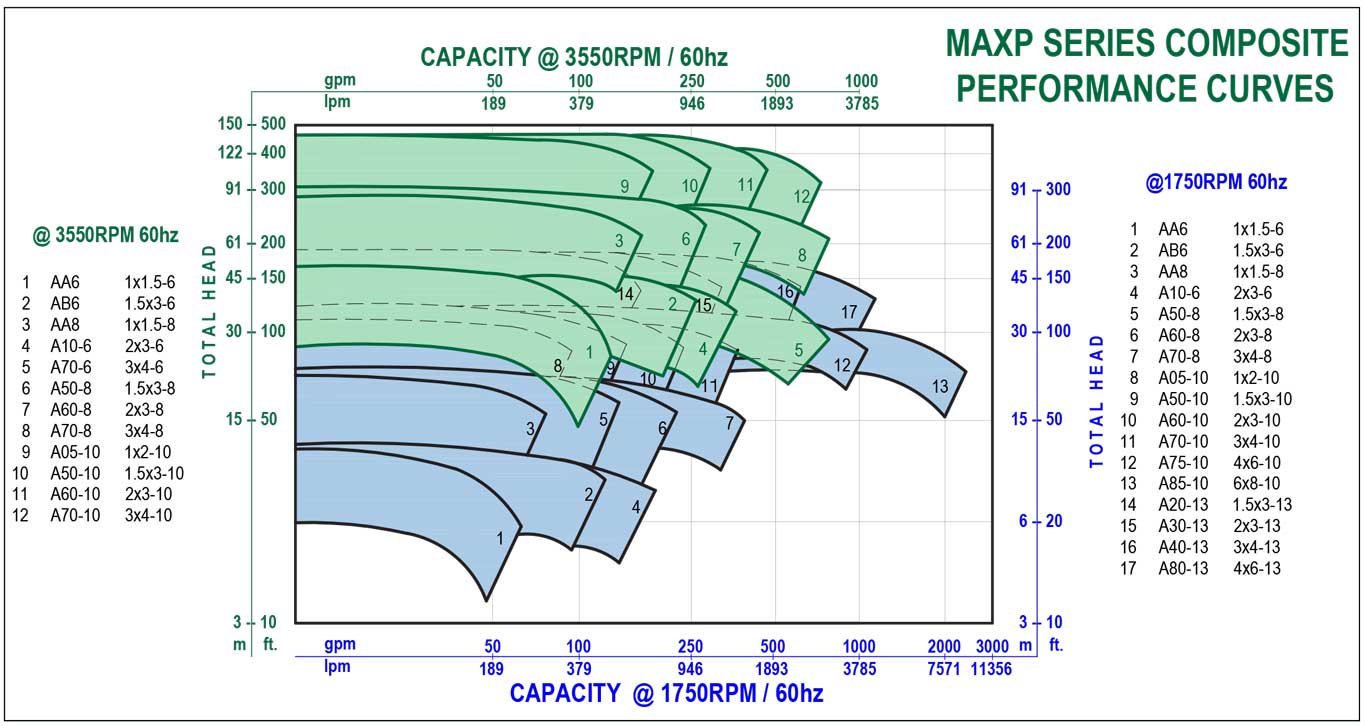

| Maximum Flow | 2000 GPM |

|---|---|

| Maximum Head | 470 FT |

| Liquid Temperature | -150° F to +800° F |

| Maximum Power | up to 200 HP |

| Connections | 150lb RF std. or opt. 300lb RF ANSI Flanges |

| Bearings | SiC, SiC-X opt. for Upset or Dry-run Conditions |

| Working Pressure | 285 psig |

| Impeller | Enclosed |

| Speeds | Up to 3550 rpm |

| Magnets | Neodymium or Samarium Cobalt for High Temp |

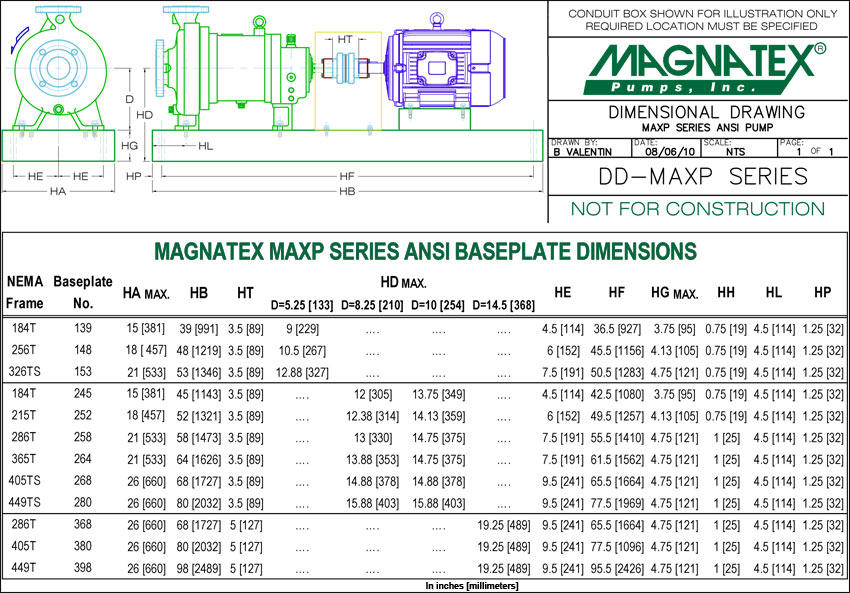

| Motor | NEMA or IEC Frame Mounted |

| Secondary Containment | Optional |

| Steam Jackets | Optional |

| External Flush | Optional |

| Recirculated Flush & Vent | Optional |

| Vortex Breakers | Optional for Improved Solids Handling |

| Centerline Mounted | Optional |