- Home

- /

- Pumps

- /

- Mechanical Seal Centrifugal Pumps

- /

- Repeller/Expeller

For Quality Management System:

(Applicable for IAS Accredited Certification)

ISO 9001: Registered

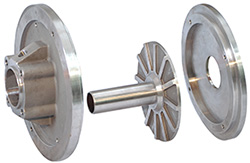

Magnatex 3596 Repeller/Expeller Series

Magnatex 3596 Series pumps and spare parts come with a 5-year unconditional warranty on materials and workmanship.

Magnatex expeller/repeller design pumps are used in applications where there is a possibility of dry run conditions, liquid slurries up to 40% or crystallizing liquids, all of which are damaging to mechanical seals or packing. Expeller/repeller/hydrodynamic seals, eliminate the need for mechanical seals or packing which means that there is no need for expensive seal cooling water or seal pot systems. The principle of operation is very simple; a repeller or pump out vanes behind the impeller and in front of the stuffing box area redirects liquid to the discharge of the pump BEFORE it enters the stuffing box area, creating an air void in the stuffing box while the pump is in operation, hence, no leakage from the pump into the atmosphere. When the pump is shut down, special dry running graphite packing prevents leaks from the stuffing box area.

Materials of Construction

Connect with a Magnatex representative to learn more about our products or to request a quote.

Contact Us

3596 Repeller/Expeller Specifications

| Liquid Temperature | -100° F to 500° F (-73° to 371°C) |

|---|---|

| Maximum Shaft Deflection | 0.002 Inch (0.0508mm) |

| Connections | 150lb FF std. or 300lb RF Optional |

| B10 Bearing Life | 50,000 Hours |

| Maximum Working Pressure | 275 psig (18.96 bar) |

| Impeller | Enclosed |

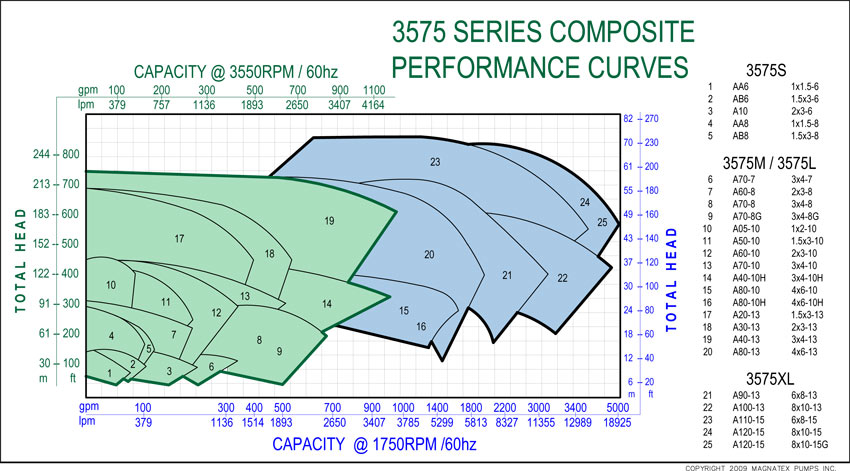

| Speed | Up to 3550 rpm (2959 @ 50hz) |

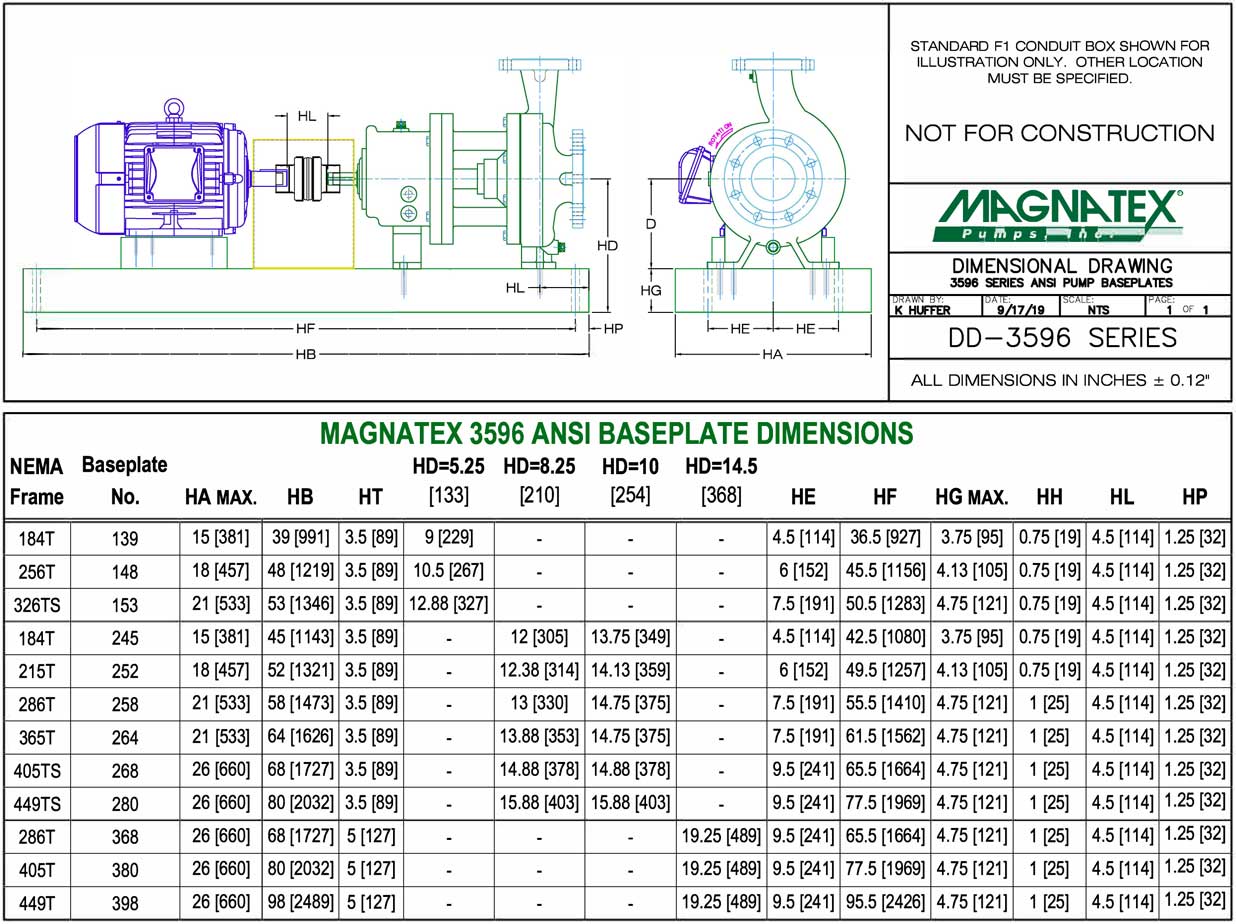

| Motor | NEMA or IEC Foot Mounted |