- Home

- /

- Pumps

- /

- Applications

- /

- Solids Handling Mag Drive Pumps

For Quality Management System:

(Applicable for IAS Accredited Certification)

ISO 9001: Registered

Metallic Sealless Mag-Drive Pumps Handle Solids

Magnatex's metallic, standard design pumps are typically limited to 1% by weight of 500 micron solids or up to 8% of 100 micron particles. The simplest way to limit larger solids and higher concentrations is to use a 40-mesh strainer on the suction. Unfortunately, this can result in the strainer plugging, which can result in "starving" the pump suction and subsequent failure of the pump.

What happens if higher concentrations of solids go through a mag-drive pump?

If percentage of solids or size exceeds the above values, provisions must be made to allow use of our models because:

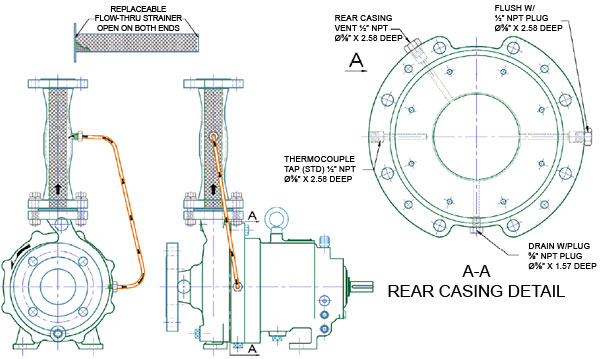

Magnatex has the answer!--"Baffle-plated," anti-vortex rear casings that break up the vortices, eliminating the potential damage caused by solids-laden vortices that can lead to a rear casing breach. This option is available with our MPL Series and MAXP Series product lines.

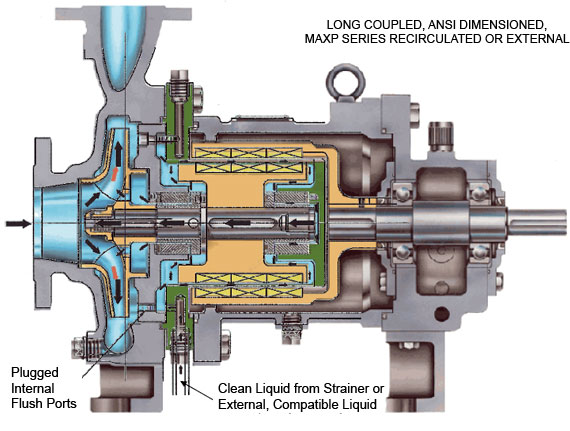

Additionally, Magnatex offers either self-cleaning or cyclone separators mounted in the discharge line with the resulting clean product flush introduced to a port in the rear casing flange after plugging of the internal flush ports. This option is available only with the MAXP Series.

Neither will disrupt the process as there is no dilution, and solids simply continue down the discharge pipe in the same concentrations as they entered the pump.

Of course, another option in conjunction with plugging of the internal flush ports would be to introduce a clean, compatible liquid to the rear casing, but care must be taken to avoid product dilution that could upset the process and to assure adequate pressure and resultant flow is always available.